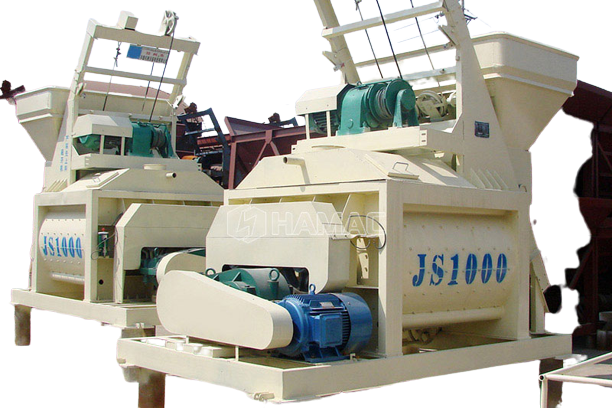

Twin Shaft Concrete Mixer For Sale

Twin shaft concrete mixer for sale, is also named double shaft horizontal concrete mixer or twin shaft compulsory concrete mixer. As a leading manufacturer of twin shaft concrete mixer for sale in Philippines, HAMAC provide our clients with the model from 0.5m3 to 4m3 per batch at different price. It is compact, intelligent, safe, quiet and reliable. This series of twin-shaft concrete mixers can mix various grades of concrete, lightweight aggregate concrete and mortar, and are suitable for commercial concrete mixing plants, mixing plant for various own projects, prefabricated enterprises, etc.

- Home

- |

- Twin Shaft Concrete Mixer For Sale

Brief introduction of twin shaft concrete mixer

The twin shaft batch mixer plays an important role in the different fields of concrete mixing. It is the most widely used concrete mixer for the different types of ready mix concrete plant for sale. It is mainly suitable for mixing dry hard concrete, plastic concrete, wet concrete, various mortars and other commercial concrete. It is equipped with automatic grease pump for lubrication, hydraulic discharge opening etc.

How many types and models twin shaft concrete mixer we provide?

HAMAC provide our clients with our JS series double shaft concrete mixer from 0.5m3 to 2.0m3. Meanwhile, HAMAC is an authorized distributor of SICOMA. So we have SICOMA concrete mixer for sales as well.

How to select the right model of twin shaft central mixer?

Normally speaking, the twin shaft central mixer does not work separately. It is always considered as a part of concrete batching plant. Its common usage is for concrete block production line, concrete pole plant etc. when you want to purchase a twin shaft compulsory concrete mixer, there are several factors need to be considered;

- Capacity, how many cubic meters per batch or per hour? HAMAC can provide our clients with the central mixer from 0.5m3 to 6m3 per batch;

- What is the discharging height of the concrete mixer? Then we will see if the platform is required, and how many meters high.

- If you need the weighing system for cement, water and additive? The weighing system is not a standard part of the concrete mixer.

Technical Data of twin shaft concrete mixer for sale

| Model | JS500 | JS750 | JS1000 | JS1500 | JS2000 | JS3000 | JS3500 | JS4000 | |

|---|---|---|---|---|---|---|---|---|---|

| Discharging Volume (L) | 500L | 750L | 1000L | 1500L | 2000L | 3000L | 3500L | 4000L | |

| Feeding Volume (L) | 800L | 1200L | 1600L | 2400L | 3200L | 4800L | 5600L | 6400L | |

| Capacity | ≥25m³/H | ≥37.5m³/H | ≥50m³/H | ≥75m³/H | ≥100m³/H | ≥150m³/H | ≥180m³/H | ≥200m³/H | |

| Maximum Aggregate Size (Pebble/Gravel)Mm | 40/50 | 40/60 | 60/80 | 80/100 | 80/100 | 80/120 | 80/120 | 80/120 | |

| Cycle Time (S) | 72 | 72 | 60 | 60 | 60 | 60 | 60 | 60 | |

| Total Weight (Kgs) | 4000 | 5500 | 8700 | 11300 | 15000 | 11450 | 12000 | 19000 | |

| Discharge Height (M) | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | |

| Mixing Blade | Rotary Speed | 35r/Min | 26r/Min | 29.6r/Min | 24.5r/Min | 24.5r/Min | 21r/Min | 21r/Min | 21r/Min |

| Quantity | 2×7 | 2×7 | 2×8 | 2×8 | 2×8 | 2x10 | 2x10 | 2x11 | 2x12 |

| Mixing Motor | Model | Y180M-4 | Y200L-4 | Y180M-4 | Y225M-6 | Y250M-6 | Y280M-6 | Y280M-6 | Y315S-6 |

| Power | 18.5kw | 30kw | 2x18.5kw | 2x30kw | 2X37kw | 2X55kw | 2X55kw | 2X55kw | |

| Hoist Motor | Model | YEZ1325-4-B5 | YEZ132M-4-B5 | YEZ160L-4 | YEZ180L-4 | YEJ180L-4 | Y25M -4 | Y25M -4 | Y25M -4 |

| Power | 5.5KW | 7.5KW | 15KW | 18.5KW | 22KW | 2 × 55 Kw | 2 ×55 Kw | 2 × 75 Kw | |

| Pump Motor | Power | 1.1KW | 1.1KW | 3KW | 3KW | 4KW | 5KW | 5KW | 6KW |

For the twin shaft concrete mixer, there are three designs for discharge gate opening. For some small concrete mixer such as JS500, for some concrete block making plant, it is designed to manual opening. For some models such as JS750, JS1000, they are designed as pneumatic opening. For the bigger models, it is hydraulic discharge opening;

We have JS500, JS750, JS1000, JS1500,JS2000, for the bigger size, usually speaking, we adopts SICOMA concrete mixer.

For the common model, we always have them in stock. For some countries, because the voltage and frequency is different from China, so we have to order the customized motor, it will take approximate 20 days.

The price depends on what you need. For a twin shaft cement mixer, the optional parts are weighing system, feeding system and support frame system. All of these factors affect the