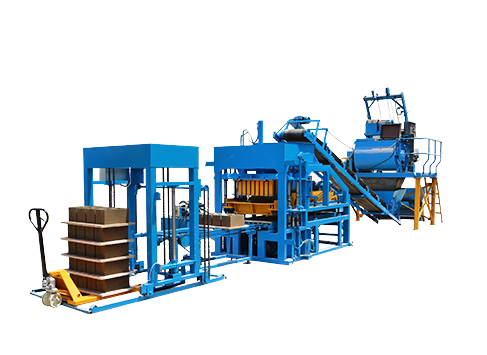

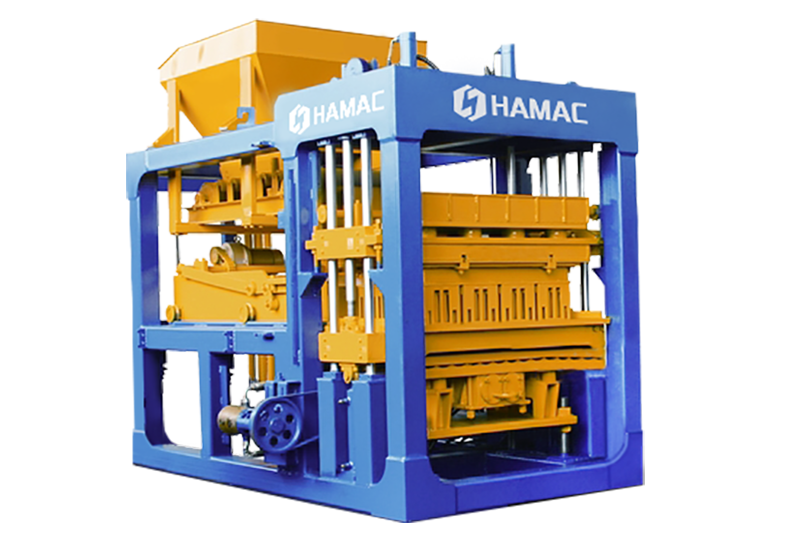

Cement block making machine For Sale

Cement block making machine is also named cement block molding machine, it is a very popular machine to produce different dimensions of cement hollow block, paver brick & decorative blocks in Philippines. It is very convenient to get the raw material, and easier to be produced compared with clay brick.

- Home

- |

- Cement block making machine For Sale

What is cement brick and cement block making machine?

Cement bricks, interlocking bricks, concrete bricks, their main raw material is fly ash,coal slag, coal gangue, tailing slag, chemical slag or natural sand, sea mud, etc. (one or more of the mentioned raw materials), cement is used as coagulating agent. So, this kind of bricks is manufactured without calcination at high temperature. Actually speaking, all the material can be solidified with cement can be used as the raw material to make the cement bricks.

Cement block making machine is also named cement block molding machine, it is a very popular machine to produce different dimensions of cement hollow block, paver brick & decorative blocks in Philippines. It is very convenient to get the raw material, and easier to be produced compared with clay brick.

Features of cement hollow block making machine

- Strength of brick, bricks of different grades of strength can be produced according to the requirements of engineering construction

- Shape, according to the needs of the project to determine the different design specifications of hollow blocks dimension, cement bricks, paver bricks etc;

- It can be used to produce hollow blocks, multi-row perforated bricks, solid bricks, paver bricks, decorative bricks, wall bricks and other concrete bricks of different varieties;

- Waste concrete bricks can also be recycled, increasing the comprehensive utilization of resources;

Different hollow block machine design in Philippines

According to different factors, we can divided the cement brick machines to many different types,

- Degree of automation, there are automatic cement brick machine, semi-automatic cement brick machine and manual cement brick making machine;

- Forming principle, there are mechanical vibration cement hollow block machine and hydraulic forming cement hollow block machine for sale;

- Mobile or stationary, there are mobile concrete hollow block machine and stationary concrete hollow block machine. The mobile type is also named as portable cement hollow block machine or egg laying cement brick machine;

The client can choose the suitable hollow block machine design for their different projects.

Look for a reliable cement brick maker manufacturer

There are many cement hollow block machine suppliers in the world, how you can find a reliable one?

- Visit the factory or working sites of the suppliers of hollow block machine in the Philippines, to check the quality firstly, to see the paint, welding etc;

- Compare the concrete hollow block production line cost, to consider the price and quality together;

- Check the after-sale service of concrete hollow block maker, to see if you can get the service shortly; HAMAC owns local office in Manila, we can provide the clients with service immediately;

- Call the clients who are using the CHB machine in Philippines to check with them how the quality is.

After considering all these factors, you will finally find a reliable concrete hollow block making machine in the Philippines.

How to choose a right model of hollow block making in Philippines

It is good business for concrete blocks. The hollow blocks price Philippines is higher and higher in these years. If you want to invest on the concrete hollow block business, there are several factors needs to be considered before purchasing,

- Your budget, it is the most important factor needs to be considered;

- What is the most popular block size, brick size or paver size in Philippines?

- What is the hollow block price, bricks pricephilippines, chb price Philippinesor paver blocks price in Philippines?

- How many pieces block or brick you want to produce per day or per hour?

- How many workers you want to employ? Then you can decide to use automatic hollow block machine or semi-automatic hollow block maker.

- Do you have enough land to arrange the concrete block machine there?

You can also contact our HAMAC expert for professional consultation. We will consider your budget and actual market condition together and then recommend you a suitable concrete hollow block production line.

Technical data of cement brick machine

QT4-15 Automatic concrete brick forming machine Main technical parameters:

| Dimension | 3600×1800×2600mm | Motor Power | 29.4KW |

|---|---|---|---|

| Mould Area | 550×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 900×550×30mm | Weight Of The Block Making Machine | 5800kgs |

QT5-20 Automatic concrete block forming machine Main technical parameters:

| Dimension | 3650×2100×2720mm | Motor Power | 20KW |

|---|---|---|---|

| Mould Area | 550×1100mm | Vibration Force | 50KN |

| Working Cycle | 16-25S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 1100×550×30mm | Weight Of The Block Making Machine | 6000kgs |

QT6-15 Automatic concrete brick machine Main technical parameters:

| Dimension | 4410×2000×2510mm | Motor Power | 36.4KW |

|---|---|---|---|

| Mould Area | 680×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 900×680×30mm | Weight Of The Block Making Machine | 6000kgs |

QT8-15 Automatic hydraulic block making machine Main technical parameters:

| Dimension | 4900x2120x2650 mm | Motor Power | 46.4KW |

|---|---|---|---|

| Mould Area | 850×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS750 |

| Size Of The Pallet | 900×850×35mm | Weight Of The Block Making Machine | 6500kgs |

QT10-15 Automatic concrete block machine Main technical parameters:

| Dimension | 7500x2500x3020 Mm | Motor Power | 50.88KW |

|---|---|---|---|

| Mould Area | 1220×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS750 |

| Size Of The Pallet | 1220×900×35mm | Weight Of The Block Making Machine | 7000kgs |

Note: Our products are being updated constantly, all rights reserved by HAMAC.

directory

- What is cement brick and cement block making machine?

- Features of cement hollow block making machine

- Different hollow block machine design in Philippines

- Look for a reliable cement brick maker manufacturer

- Technical data of cement brick machine