The Best Heavy Earth Moving Equipment for Your Needs

Table of Contents Introduction When it comes to heavy construction, mining, or earthwork projects, having the right equipment at your disposal can be the key

Stone crusher plant is a production line combines with different types of stone crusher for sale philippines, vibrating feeder, vibrating screen and belt conveyors etc. It is used to crush the big size rocks from quarry or river stone to aggregates such as G1, 3/4’’, 3/8’’ and fine sand 1/4’’. For some working sites, if the raw material is not so clean, the sand washing machine will be equipped to wash the sand and aggregates to be clean. HAMAC will provide you with the stone crusher plant for sale based on your detailed requirement. The capacity of aggregate crushing plant we can provide are from 30-1000 tph.

Stone crusher plant is a production line combines with different types of stone crusher for sale philippines, vibrating feeder, vibrating screen and belt conveyors etc. It is used to crush the big size rocks from quarry or river stone to aggregates such as G1, 3/4’’, 3/8’’ and fine sand 1/4’’. For some working sites, if the raw material is not so clean, the sand washing machine will be equipped to wash the sand and aggregates to be clean. HAMAC will provide you with the stone crusher plant for sale based on your detailed requirement. The capacity of aggregate crushing plant we can provide are from 30-1000 tph.

A complete stone crusher plant for sale includes material feeding, primary crusher, secondary crusher, tertiary, screening machine, and belt conveyor system. If you want to produce artificial sand, a sand-making machine and washing machine are also required. When choosing a suitable stone crusher machine for sale, you must consider the capacity requirement and raw material factors. Hereby is the detailed analysis;

When you decided to build acrushing plant for sale in the Philippines, there are several factors need to be considered to choose the suitable stone crusher machine. It is very import for the clients to know these.

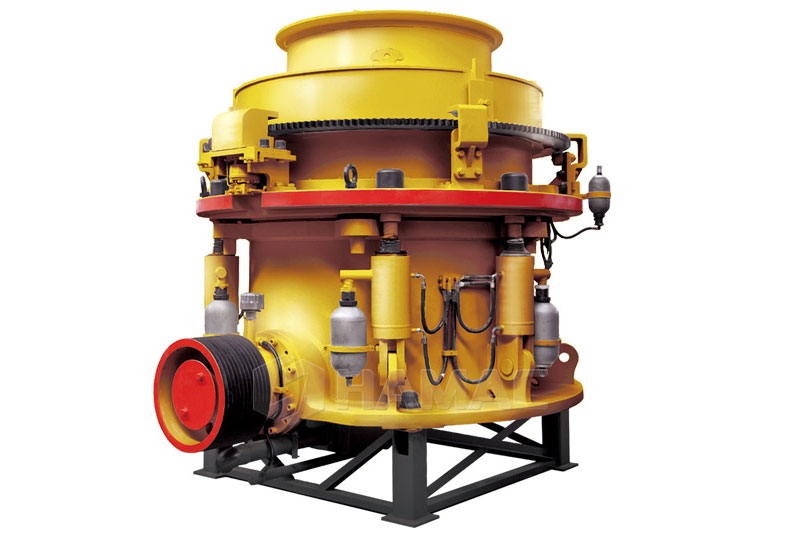

When choosing the configuration of the stone crusher plant, it is necessary to fully consider the specific factors affecting various types of crushing equipment, and select suitable crusher machine for processing different materials. Usually, a series of fragile materials with low Mohs hardness, such as limestone, talc, cement and other fragile materials below medium hardness, are recommended to use jaw crusher, impact crusher, etc. for crushing operations. For granite, basalt, andersite, river stone etc., it is recommended to use equipment with high chrome parts and high wear resistance wearing parts, such as cone crusher for production, then the stone production line can be reasonably adjusted.

A reasonable stone production line is bound to consider the mutual cooperation between various equipment. Only with reasonable design and good cooperation between all equipment can greater production value be created.

At present, the supply of natural aggregates and sand is in short supply, and the natural sand and aggregates existing in nature can no longer meet the current demand for the construction in Philippines. The artificial sand and gravel have won the favor of many end users with their uniform particle size, excellent cubical shape and reasonable price. At present, artificial sand and aggregates have been widely used in many departments such as municipal construction, urban construction, road paving and concrete batching plants. Therefore, investors who saw the profit of sand and aggregates projects raised funds one after another, bought artificial sand making equipment, and set up sand and aggregates factories.

The following points must be understood before investing in a sand and gravel production line:

Regarding the stone crusher plant price in Philippines, you have two ways to purchase the stone crusher for sale. One is you import it from China or other countries directly, another way is you purchase it from stone crusher company locally who is a distributor there. For these two ways, the stone crusher machine price is different.

You can purchase it from the local distributor or the stone crusher company who has branch and local partner in Philippines. Then you can just want to consider the price which is quoted by stone crusher Philippines local suppliers. No need to consider the cost for tax and other cost. Because it is already included in the quotation. For this option, it will be very convenient for the operation and maintenance of stone crusher plant in the future. The stone crusher parts and service can be got locally. HAMAC owns local branch in Manila, Philippines.

Table of Contents Introduction When it comes to heavy construction, mining, or earthwork projects, having the right equipment at your disposal can be the key

Concrete planters are not just functional additions to your outdoor space; they can also serve as beautiful decorative elements. Whether you’re a gardening enthusiast or

In the world of construction, efficiency and cost-effectiveness are paramount. Concrete production forms the backbone of countless construction projects, and the key to achieving optimal

The Magic of Earth Moving Machines Few things are more captivating than watching a giant earth-moving machine go to work – be it a bulldozer,

Recent Trends in Concrete Pump Machines Over the past several years, there has been an exciting revolution in the concrete pump industry. New technologies and

The Concrete Mixer Truck: A History People often think of a concrete mixer truck as being an industrial-sized truck equipped with a cylindrical drum to

Its HS code is 84742090, you can check the tariff cost from the customs with this code

The price of Stone Crusher Plant For Sale related to the model, new or used Stone Crusher Plant For Sale etc. It is a too wide range. You have to contact our sales manager for more information.

For the Stone Crusher Plant maintenance, it is simple, not so complicated as cone crusher. The tear and wear parts are side liner board, Stone Crusher Plant. You just want to lubricate it with grease per shift. And check the jaw plate frequently to see when to replace it.

Yes, we have local office in Malabon, Manila.

WhatsApp us