STATIONARY CONCRETE BATCHING PLANT

Stationary concrete batching plants are frequently employed in large and medium-scale projects involving water conservancy, electric power, bridges, and other construction ventures characterized by significant concrete volume, extended construction periods, and concentrated work sites. The utilization of stationary plants in such projects is driven by their exceptional level of mechanization and automation, resulting in high productivity.

- Home

- |

- Stationary Concrete Batching Plant

What Is Stationary Concrete Batching Plant

Stationary concrete batching plant is a kind of ready mix concrete plant fixed on the foundation. It is best suited for large-scale concrete production projects that require relatively high concrete production capacity and will be carried out at the same location for a long period of time. Stationary concrete mixing plant is designed to provide high efficiency, high capacity, high output and reliability of work.

Stationary concrete batching plants for sale in Hamac include various models, which can provide different production capacities. Compared to other types of concrete batching plant, the stationary type with the highest efficiency and production capacity is usually the first choice for large-scale projects that require high performance.

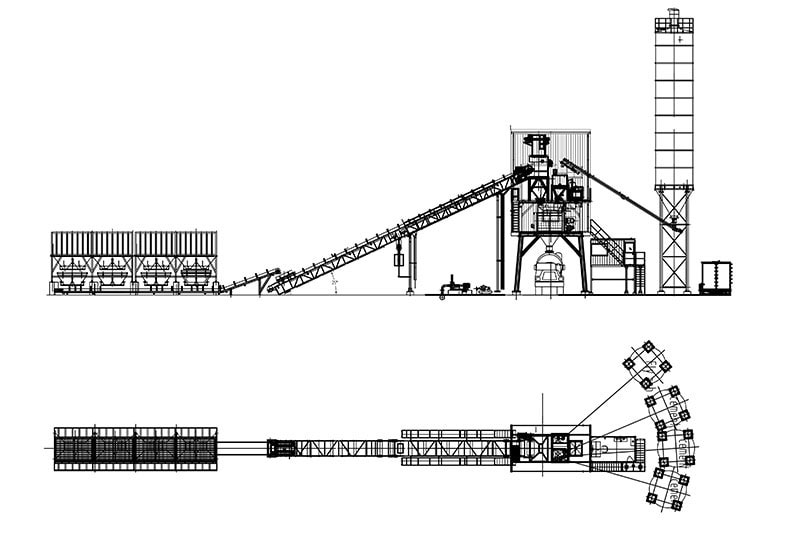

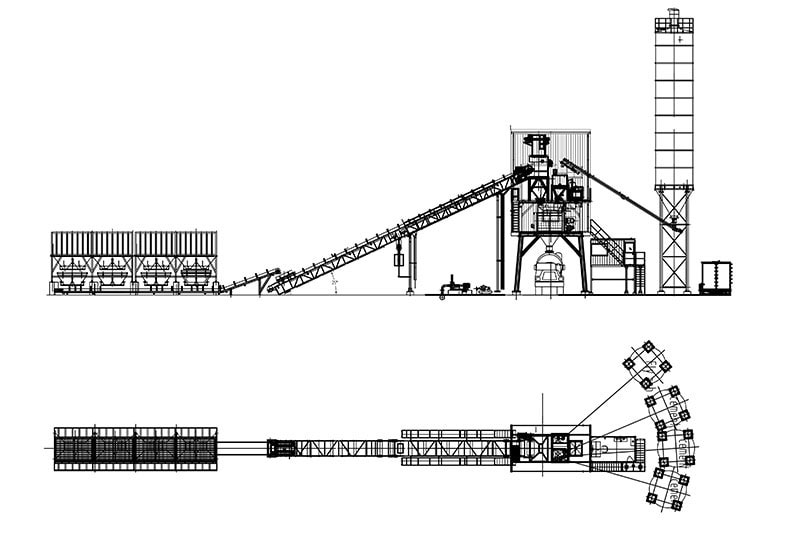

Overall Layout of The Two Typical Concrete Batch Plants For Sale

What Are Advantages of Stationary Concrete Mixing Plant

- The majority of stationary concrete mixing plants feature a modular design, a compact structure, and effortless installation.

- Stationary concrete mixing plants offer a high degree of configuration flexibility. They can be designed in multiple ways to accommodate various placement schemes in different installation areas, effectively meeting the diverse configuration requirements of users.

- Stationary concrete mixing plants are characterized by their impressive production capacity and outstanding performance. With a single mixer, these plants can achieve concrete production capacities ranging from 30m3/h to 200m3/h, while utilizing double mixers can further enhance the capacity to reach up to 400m3/h.

- Stationary concrete mixing plants are known for their durability, boasting a sturdy structure that ensures safe transportation and guarantees a long working life.

- Maintenance of stationary concrete mixing plants is made convenient and efficient. These plants feature a spacious maintenance platform that allows easy and safe access to the main components and weighing scales of the mixer, facilitating quick and hassle-free maintenance tasks.

- Stationary mixing plants are typically designed as wet-type plants, although they can also be configured as dry-type plants or as a combination of both wet and dry processes.

- Stationary mixing plants possess a robust ability to withstand environmental challenges. With the addition of special equipment designed for winter conditions, these plants can effectively produce concrete even in extremely cold temperatures as low as -30°C.

- Transporting stationary concrete plants is made easy due to their design, which is specifically tailored for container shipping.

Stationary concrete plants are equipped with computer control systems, ensuring easy operation and providing stable working performance. They operate within closed spaces, promoting equipment environmental protection.

Models of Stationary Concrete Batch Plant For Sale in HAMAC

| Technical data | Model | ||||||

|---|---|---|---|---|---|---|---|

| HZS60 | HZN60 | HZS90 | HZN90 | HZS120 | HZS180(150) | HZS240(200) | |

| Theoretical capacity(m³/h) | 60 | 60 | 90 | 90 | 120 | 180(150) | 240(200) |

| Mixer model | JS1000 | MP1000 | JS1500 | MP1500 | JS2000 | JS3000 | JS4000 |

| Batching system | PLD1600 | PLD1800 | PLD2400 | PLD2400 | PLD3200 | PLD4800 | PLD6400 |

| Discharging height (mm) | 4100 | 4840 | 4100 | 4100 | 4100 | 4100 | 4100 |

| Maximum aggregates size(mm) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) |

| automatic Cycle time(s) | 60 | 60 | 60 | 60 | 60 | 60(72) | 60(72) |

| Weighing Precision of Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Weighing Precision of Cement | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Weighing Precision of Water | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Weighing Precision of Additive | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Total power(KW) | 106 | 114 | 145 | 145 | 175 | 215 | 295 |

How Do Stationary Concrete Batching Plants Work

Stationary concrete batching plants primarily consist of a mixing console, material weighing system, material conveying system, material storage system, control system, and other supporting facilities.

The main operating principle of stationary concrete batching plants involves the utilization of cement as the binding material. Fly ash, cement, coarse sand, fine materials, and various powders are proportionately measured and weighed through the batching machine.

Once the weighing process is completed, the operator initiates the sand and stone belt motor, which transports the weighed ingredients to the weighing hopper.

Subsequently, additives and water are added to the ingredients, and they are mixed together in the mixer.

Once the desired mixing effect is achieved, the mixture is discharged into an open concrete tank truck and transported to its intended destination.

The stationary RMC (Ready-Mix Concrete) plant employs a comprehensive control system to oversee the entire operation of the machine. Computer-aided controls are utilized to facilitate the swift and precise measurement of input ingredients.

directory

- What Is Stationary Concrete Batching Plant

- Overall Layout of The Two Typical Concrete Batch Plants For Sale

- What Are Advantages of Stationary Concrete Mixing Plant

- Models of Stationary Concrete Batch Plant For Sale in HAMAC

- How Do Stationary Concrete Batching Plants Work

- WHAT ARE COMPONENTS OF STATIONARY CONCRETE MIXING PLANT

WHAT ARE COMPONENTS OF STATIONARY CONCRETE MIXING PLANT

The aggregate batching equipment plays a crucial role in the stationary concrete plant. Based on the formula entered into the software system, the weights of various specifications of aggregates and sand are measured accurately. Subsequently, the materials are conveyed to the concrete mixer. The control system takes charge of the aggregate weighing and discharge process, ensuring precision. In case of overweight tare weight, the microcomputer automatically triggers an alarm, and the tare weight resets to zero upon subsequent weighing.

The stationary concrete plant employs an aggregate lifting system, which can be either a belt conveyor or a lifting hopper. Once the sand and gravel are accurately measured by the aggregate batching machine, they are loaded into the aggregate bin. Subsequently, the materials are transported to the mixer using a lifting hopper or a belt conveyor.

The central concrete mixer serves as the primary equipment for producing concrete, capable of thoroughly blending raw materials such as cement, sand, stones, and water admixtures. It comprises essential components such as a motor, reducer, mixing tank, and discharging mechanism. At our company, the stationary concrete batching plants available for sale are primarily equipped with twin-shaft concrete mixers.

The cement silo is a storage facility designed for cement and fly ash. It features upper and lower material positions for efficient storage. The powder is introduced into the silo from the top, and a dust removal device is installed at the upper part to minimize the load pressure and prevent air pollution caused by dust.

The stationary concrete plant incorporates a cement, water, and admixture weighing system. Weighing sensors are installed on the respective weighing buckets for each material, ensuring accurate measurement.

The main building support of the stationary concrete plant includes ladders, platforms, guardrails, steel brackets, and other components necessary for structural integrity and safety.

The stationary concrete plant is equipped with an admixture supply system to cater to projects requiring the addition of water-reducing agents and other admixtures. This system enables the supply of additives necessary for producing water-reducing concrete and accelerating the concrete setting process.

The stationary concrete plant incorporates a pneumatic system that includes an air compressor. This air compressor serves as the air source for operating cylinders and butterfly valves, enabling their smooth opening and closing.

The stationary concrete plant features an electrical cabinet and a software control system. By simply inputting the desired formula into the system, all programs can be automated and executed accordingly.

WHAT ARE TYPES OF STATIONARY CONCRETE BATCHING PLANT

According to the conveying method of aggregate, there are generally two types of stationary concrete batching plant, one is belt conveyor type stationary concrete batching plant, and the other is hopper type stationary concrete batching plant. Meanwhile, it can also divided into wet type and dry type stationary concrete batching plant according to the type of concrete produced.

Features of Belt Type Stationary Concrete Batching Plant

The weighed aggregate is efficiently transported to the transition hopper through the belt conveyor. Although the design of the belt conveyor is more intricate compared to a hopper, it offers higher feeding and conveying efficiency. This makes it suitable for swiftly completing large-scale operational requirements and increasing production efficiency by over 20%.

With its short feeding cycle, high capacity, flexible configuration, and exceptional production performance, the belt-type stationary concrete batching plant is well-suited for commercial concrete mixing stations.

Features of Skip Hoist Type Stationary Concrete Batch Plant

The skip hoist type stationary concrete batch plant is a concrete mixing plant that utilizes hoppers to lift aggregates. It offers several advantages such as a small footprint, making it suitable for narrow spaces with limited room. The simple structure allows for quick installation and easy relocation. Additionally, the skip hoist type plant is often considered an affordable option, making it a popular choice for small-scale ready mix concrete production.

WHAT KIND OF CONSTRUCTION SITE CAN A FIXED CONCRETE MIXING PLANT BE USED FOR?

Stationary concrete batching plants are widely favored by ready-mix concrete producers due to their advantages in mass production, high performance, and flexibility. These plants are commonly used by concrete suppliers who sell their products to construction companies and other concrete users.

The stationary concrete equipment is particularly well-suited for construction projects that demand high-quality concrete production, including road construction, dam projects, airport construction, and more.

Moreover, stationary concrete mixing plants find application in specialized concrete production requirements. This includes the production of cylindrical compacted concrete, concrete parquet, concrete pipes, precast elements, hollow concrete floor slabs, and various other specialized concrete products.