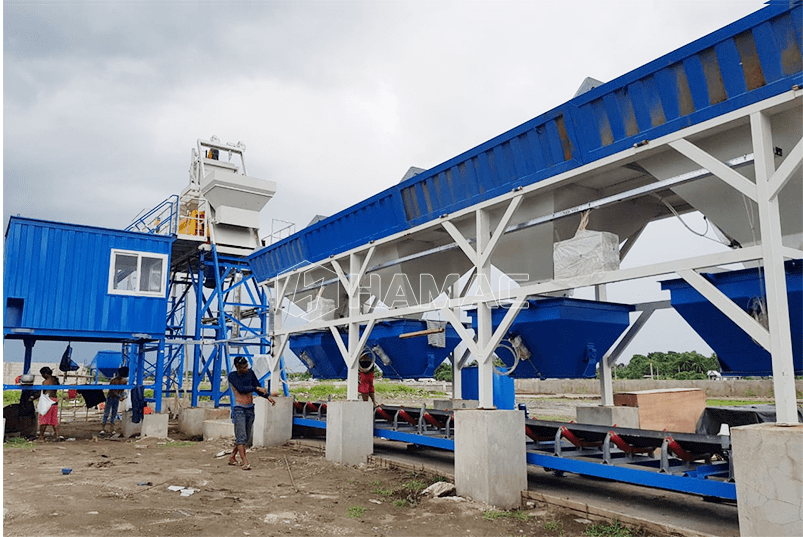

HZS50 skip hoist type concrete batching plant in Cebu, Philippines

For these two years, we delivered and installed several units of HZS50 skip hoist type concrete batching plant to Cebu, Philippines. The aggregate is lifted by the hoisting hopper to the central concrete mixer. It saves the working area occupation and cost. It is a very popular design in this area. We exported this design concrete batch plant to Philippines for several units.

Detailed information of HZS50 Concrete batch plant for sale

- Nominal capacity: 50m3/h;

- Aggregate batching machine: 4*10m3 ;

- Central mixer: JS1000 twin shaft concrete mixer;

- Cement hopper and screw conveyor to feed the cement from BIGBAG;

- Control Mode: Full automatic, easy operation;

- Discharging height:4000mm;

For different clients, they have different request for the machines and investment because of different conditions, so we always provide our clients with different design ready mix concrete plant to meet their needs.

1. In this area, there is not any cement factory to supply the bulk cement in the tank truck, so they have to use the cement in the BIGBAG. The cement silo for bulk cement is not a good option. So, all of them chose a cement hopper to collect the cement from the BIABAG. There is a blade in the hopper. The BIGBAG will be cut, and then the cement will be discharged into the hopper. And then it will be transferred to the small cement silo which is connected with the cement weighing hopper;

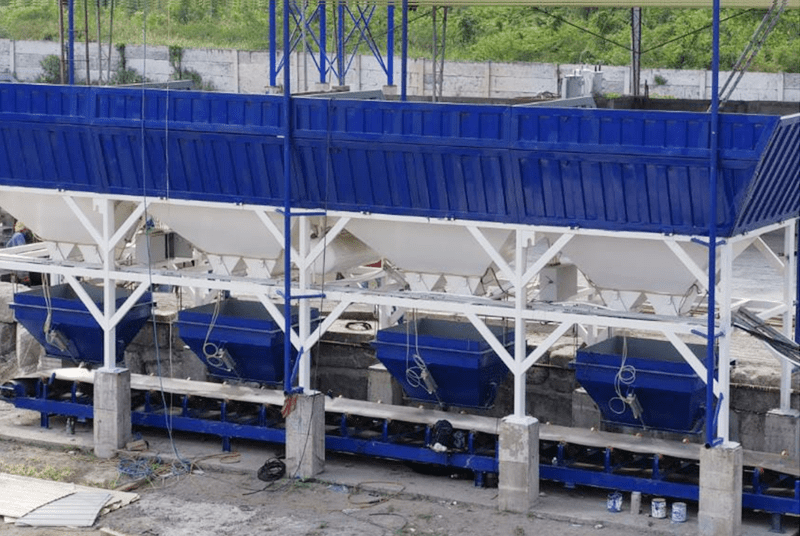

2. Some clients need more accurate and faster weighing system. We have two options for the aggregate weighing system. One is multiple times weighing, all the aggregates and sand will be weighed in the same hopper, it will take more time and not so accurate. Another design is separate weighing for each sizes aggregates. It is more accurate. As a manufacturer of concrete batching plant for sale, we can provide you with these two solutions.

Together weighing system

Separated weighing system

Frequently asked questions

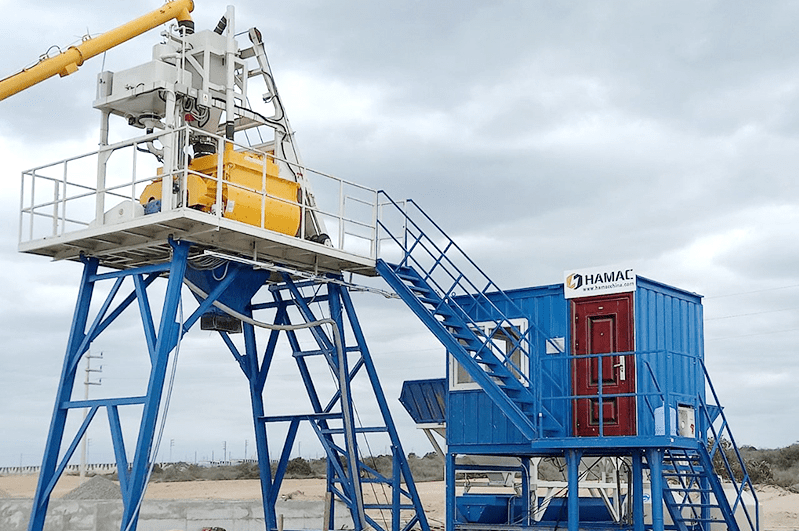

1. Which kind of cement mixer for sale is used for the skip hoist type concrete batch plants?

Normally speaking, JS series twin shaft concrete mixer machine is the most popular one. For some clients who want to produce higher quality concrete for precast parts, the planetary concrete machine mixer will be used.

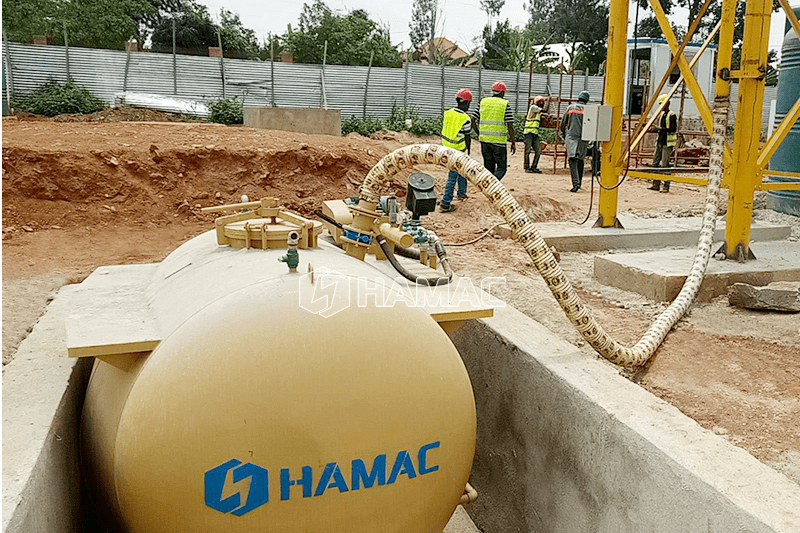

2. If there is not bulk cement at site, only BIGBAG cement, how can I feed the cement?

For the bulk cement, we will recommend the clients to use the bolted type cement silo for sale. If there is only BIGBAG cement at site, you can use a mini silo for sale and a screw conveyor to feed the cement, no need to use the cement silo;

3. How long it will take to install the batching plant Philippines?

For the skip hoist type concrete batching plant, it is more simple structure than belt conveyor type concrete batch plant, it will take approximate 2 weeks to finish all the installation and commissioning.

4. How long is the guarantee period?

HAMAC provide 1 year guarantee after installation and commissioning, but tear and wear spare parts are excluded;

- HZS50 skip hoist type concrete batching plant in Cebu, Philippines

- Detailed information of HZS50 Concrete batch plant for sale

- Frequently asked questions

- Which kind of cement mixer for sale is used for the skip hoist type concrete batch plants?

- If there is not bulk cement at site, only BIGBAG cement, how can I feed the cement?

- How long it will take to install the batching plant Philippines?

- How long is the guarantee period?