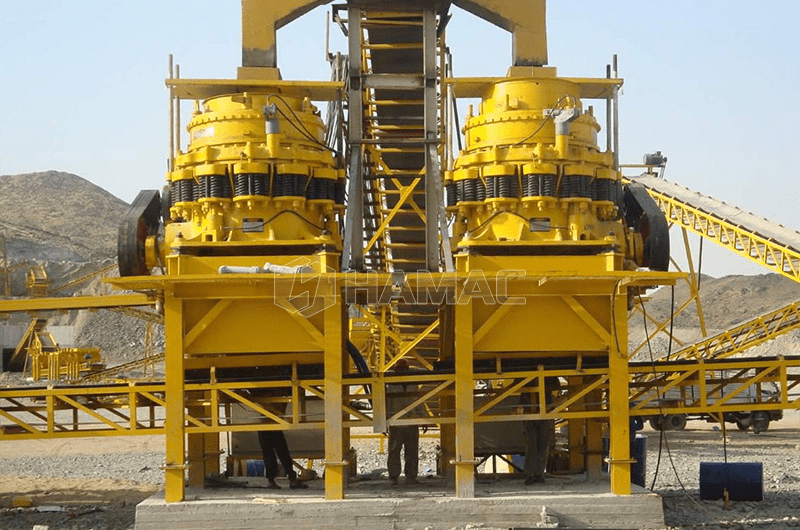

Cone Crusher For Sale

Cone Crusher For Sale

Cone crusher for sale can be widely used in metallurgical, construction, chemical and building material industry, suitable for hard and medium hard materials such as mine ore, limestone, quartz, granite, sandstone, river stone and so on. It is proven that the crusher with good performance and reliable quality has gain the customers’ praise. It is an ideal cone crusher for secondary and tertiary crushing.

According to our experience, most of the clients in Philippines want to crush the river stone which is hard material. Cone crusher is the best choice for the hard materials.

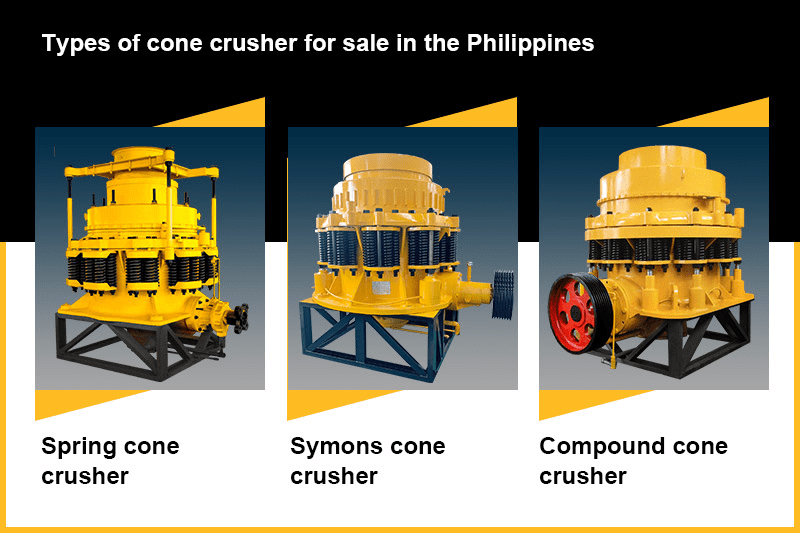

There are many different types of cone crusher for sale in the Philippines market now. They are spring cone crusher, compound cone crusher, multi-cylinder hydraulic cone crusher and single-cylinder hydraulic cone crusher. All the cone crushers work with same working principle, the difference is that some cone crushers are optimized, they are more powerful and stable. Hereby we only introduce the three types which are more popular in the Philippines.

1. Spring cone crusher, this is the first generator cone crusher in the world. It was very popular in the world in the past years when the technology is not so advanced. The springs are equipped on the crusher machine as a safety device;

2. Symons cone crusher, it is spring type cone crusher as well. It was invented by SYMONS brothers. That is why it was called Symons cone crusher. It is more advanced than the common spring cone crusher, it is equipped with hydraulic cylinder to clear the crushing chamber if it is choking by hard big stone or metal in the crushed material;

3. Compound cone crusher, it is the same as Symons cone crusher, but its design is stronger. And it is easier to replace the mantle and concave. There is no need to inject filler material between the mantle and concave. It will save the time for maintenance.

These are the three different types spring cone crusher in the market now. They were being sold in the market for many years. The technology is mature and stable. They are the good choice for the Philippines market.

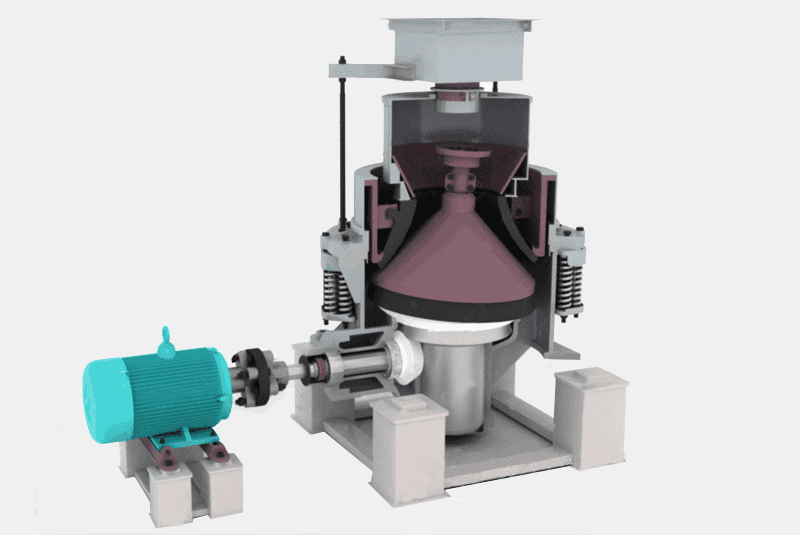

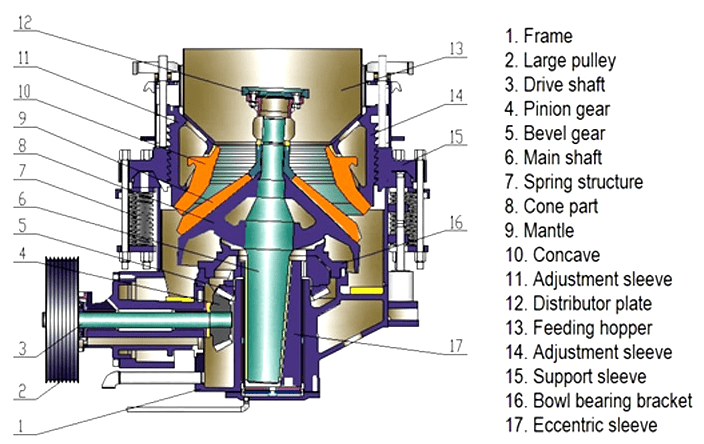

When the machine is working, the moving cone of the crusher makes a swinging motion around the fixed point. Therefore, the crushing walls of the movable cone and the fixed cone of the crusher are sometimes approached and sometimes separated, so that the materials are continuously impacted, squeezed and bent in the crushing cavity to realize the crushing of the materials, and complete the crushing and discharging. The surface of the crushing cavity is covered with a wear-resistant high manganese steel lining plate. The size of the discharge opening is adjusted hydraulically or manually.

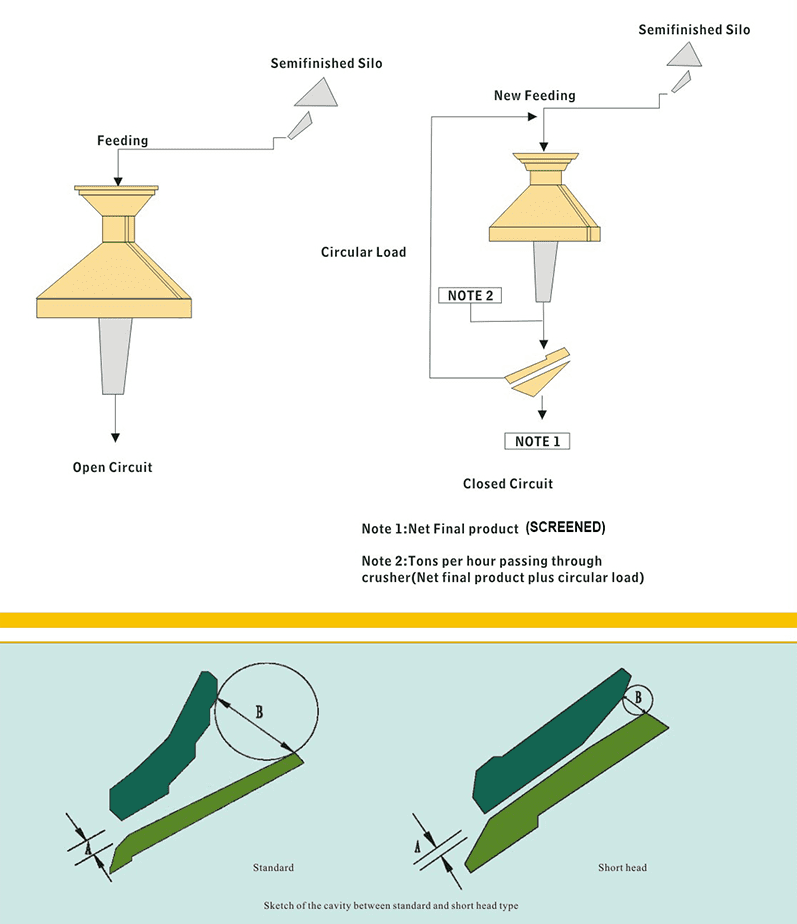

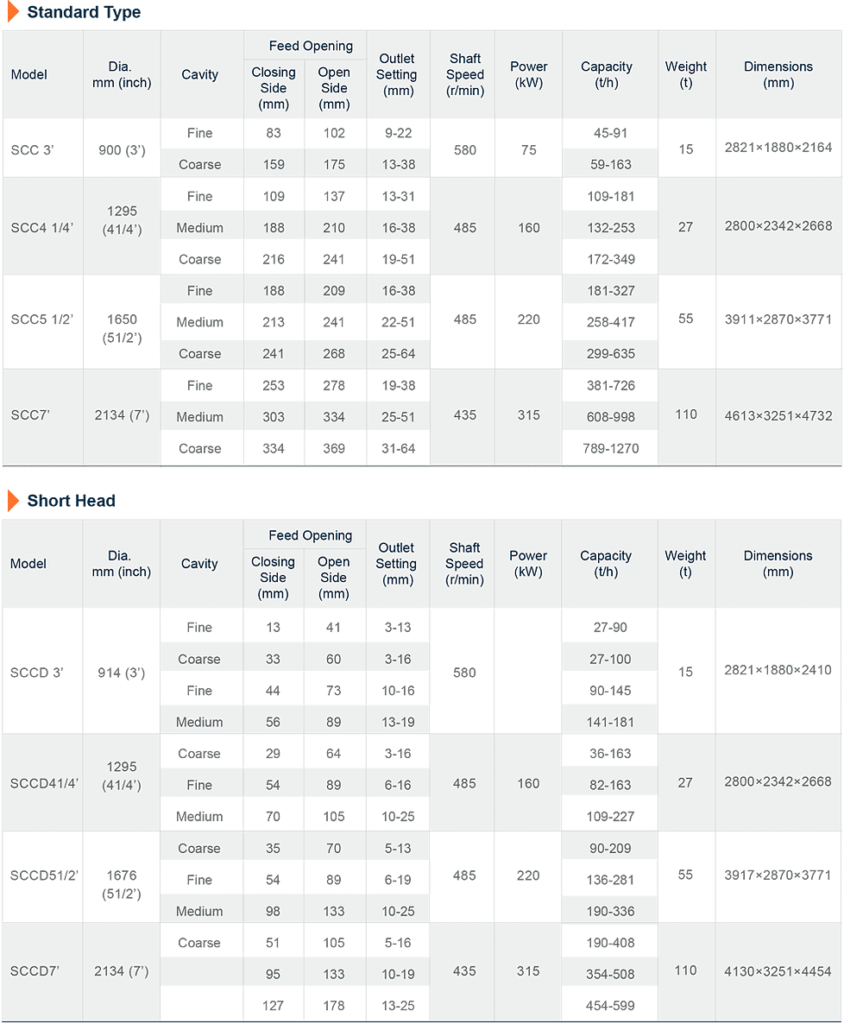

For Symons cone crusher, there are two different types for different usage. Standard type cone crusher is always used as a secondary crusher, its feeding opening and discharge opening is bigger. It is for coarse crushing. In the final crushed stone from the standard type cone crusher, the bigger size aggregate will be more. The short head cone crusher is always used as a tertiary crusher, its feed opening and discharge opening is smaller, usually speaking, the final product from this cone crusher, most of them are smaller sizes aggregates and sand. For example, when the client want to get the aggregates 0-40mm, and most of them are 20-40mm, the standard type cone crusher is more suitable. When the client wants to get the aggregate 0-40mm, but most of them are 0-20mm, then the short head cone crusher is more suitable.

● Have many types of crushing cavity. The S series cone crusher possess special design, and the customers can choose the type of crushing cavity which has high efficiency, uniform granularity, good shape, uniform abrasion and long use life of bowl liner and mantle. There are standard type cone crusher and short head cone crusher as options;

● High capacity. Compared with other types of the crusher, the series of S cone crusher has longer crush arm, larger stroke, higher crushing force. It can crush the material more efficiently.

● Every stroke crushes more material.

● The mantle of S series cone crusher leaves bowl liner further in every stroke, so the crushed material is much more at every stroke, and the materiel pass through the cavity more quickly. As a result, the capacity is increased by many times;

● Low cost of daily run and maintenance. The component of tear and wear parts and structure is better, prolong the use life; the long crush arm to reduce the load of slip bearing, gear, and shell; the granularity of the product is uniform, so the circular load is less; the system of cleaning cavity with hydraulic pressure is convenient , save time, low power and distribution in reason.

In Philippines, most of the project is for river stone crushing. Because there are much sand in the raw material, it will be screened by the vibrating screen firstly to take out the sand and small sizes aggregates, and then the bigger stone will be crushed by cone crusher. Here below is a typical crushing and screening plant for your reference.

Note: Our products are being updated constantly, all rights reserved by HAMAC.